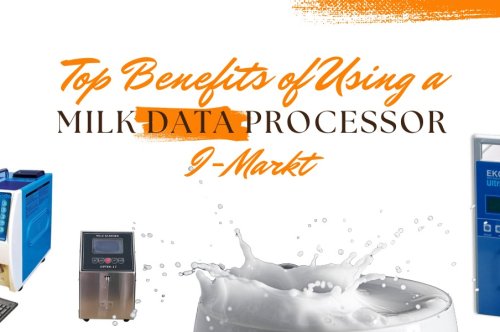

How Milk Testing Helps Boost Dairy Business Profits

The business of milk is booming and growing, and it’s not hard to see why! With increasing demand for dairy products worldwide, especially in emerging markets, this is a business with plenty of growth potential. One often overlooked yet incredibly powerful strategy to increase profits is milk testing. Regular and reliable testing not only ensures the quality of milk but also opens up new ways to optimize costs, boost customer satisfaction, and meet regulatory standards. Let’s dive into how milk testing can transform your dairy business into a more profitable and efficient operation.

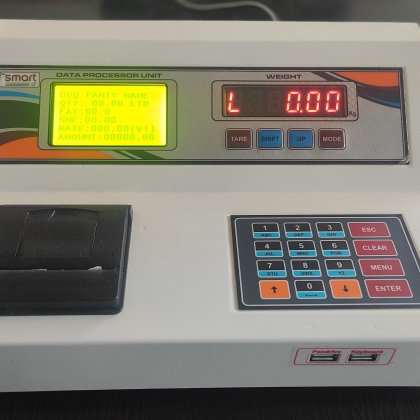

Milk testing refers to the process of analyzing milk samples to determine their composition, safety, and quality. By evaluating these parameters using modern equipment like milk analyzers or portable milk testers, dairy businesses can make informed decisions that directly impact production, sales, and customer trust.

Accurate Quality-Based Payments

One of the key benefits of milk testing is the shift from volume-based to quality-based payments. Traditionally, milk suppliers were paid solely based on quantity. However, with milk analyzers, dairy businesses can now pay farmers based on fat and SNF content.

This system motivates farmers to deliver better-quality milk, reducing contamination and improving yield. As a result, processors receive high-quality input, which translates to better end products. This creates a win-win scenario—farmers are rewarded fairly, and dairy processors increase their product value.

Reduction in Adulteration and Spoilage

Adulteration is a major issue in the dairy industry, especially in regions where milk travels long distances. Contaminants like water, soda, starch, and even harmful chemicals are often added to increase milk volume. Regular milk testing allows immediate detection of such adulterants, ensuring only pure milk is processed.

Early detection through tools like milk adulteration test kits also helps prevent costly spoilage during pasteurization and packaging. When poor-quality milk enters the supply chain, it can ruin entire batches, leading to losses in both time and revenue.

Enhanced Operational Efficiency

Milk testing doesn’t just stop at the farm level—it plays a critical role in processing plants and chilling centers as well. With the help of automated milk analyzers, processors can screen large volumes of milk within seconds, ensuring consistency and safety across all batches.

Moreover, knowing the exact composition of the milk helps in:

Calibrating machinery accurately

Reducing chemical usage during pasteurization

Optimizing storage and transportation

Boosts Brand Reputation and Customer Loyalty

In the age of health-conscious consumers, quality and safety are more important than ever. Customers today want assurance that the milk they consume is free from contamination, packed with nutrition, and processed under hygienic conditions.

Milk testing supports this narrative. By showcasing lab-tested results and maintaining consistent product quality, dairy businesses build strong consumer trust. This can lead to long-term brand loyalty, repeat purchases, and a premium brand image—factors that directly impact revenue and market positioning.

Regulatory Compliance and Export Readiness

Government agencies such as FSSAI and BIS have strict regulations regarding milk composition and hygiene standards. Regular milk testing ensures compliance with these norms, helping businesses avoid hefty fines, shutdowns, or product recalls.

For businesses looking to expand internationally, milk testing becomes even more important. Export markets demand high-quality dairy products, and without proper documentation of quality assurance, businesses may miss out on lucrative opportunities.

Long-Term Profit Planning

Beyond day-to-day testing, data collected from milk analyzers and digital logs can help dairy businesses forecast trends, monitor supplier performance, and identify problem areas. Over time, this data becomes a strategic asset, enabling better pricing strategies, supplier negotiations, and inventory planning—all key to increasing profits.

How Our Products Can Help You Achieve These Benefits

At BigBuyZone, we offer a wide range of milk testing equipment that empowers dairy businesses to improve quality, reduce losses, and increase profitability.

Milk Analyzer Machines

Our machines are designed for fast, accurate readings of fat, SNF, density, and added water. Ideal for dairies, milk collection centers, and cooperatives.

Portable Milk Testers

Lightweight and easy to carry, our portable testers are perfect for on-the-go testing in remote villages and collection points. Immediate results, anywhere you need.

Milk Adulteration Test Kits

Detect harmful substances like starch, soda, detergent, urea, and more in seconds. Stay ahead of adulteration and ensure only high-quality milk enters your supply chain.

Milk Collection Accessories

From test tubes to measuring jars and sample bottles, we provide everything you need for professional-grade milk testing at your facility.

Conclusion

Milk testing isn’t just a quality control measure—it’s a profit-driving strategy. From reducing spoilage to rewarding quality, from meeting compliance standards to winning customer trust, every benefit of milk testing leads to a stronger, more profitable dairy operation.

Invest in the right tools today and watch your dairy business grow—not just in volume, but in value.